Finally getting a chance to sit down and write down my

thoughts on my first ever NERPM meet. That combined with a minor surgery the

following day the last few days have seemed like a whirlwind. Good news all is

that I am on the road to recovering and some time off work lets me fully gather

my thoughts on this experience and also finally elaborate on a major project I

am apart of. But first let’s talk about the preparing for the show itself.

I spent the week before working late into the night to try

to complete as many projects as I could or at least to a point where I was

happy to present them. Some of you may have seen on my Facebook group that I

had another minor injury towards the end of the week. Once again please be very

careful when using superglue (CA) with the accelerator. Part of the skin was

thorn off when trying to properly clean the glue off and it really caused some

damage. Because of this I was lost two days of work hauling most of the

projects I wanted to work on. Meaning that I was not able to finish 3025’s

replacement parts nor getting all of 0901’s paint work complete. The other minor setback came in the way of my

Anycubic Photon S’s LCD screen cracking. This put the printer out of action and

made me have to make due with parts I had already created. Not the end of the

world but combined with the finger injury was a soar note on the whole process.

Thankfully my finger is healing and a new LCD screen arrived in the mail today,

so both issues will soon be in the past.

I set out for the show Friday Morning and arrived around

7:45 am to check in and start setting up my models.

|

| My Section of Display Table. Chris Adams to my Right |

In addition to 3025,0901, FVRR PRR Caboose, and Strasburg

Thomas; I also decided at the last minute to bring my older Walt Disney World

Railroad Models in a way to show my progression as a modeler. These WDW models

were some of the first I made in my college dorm room no less which meant I had

very limited tools and supplies. Looking back at them I’m a little embarrassed

by their overall craftsmanship but they will soon have their time to reenter

the workshop for their overhauls. Still, they did manage to get some positive

reaction from some of the meet attendees which make me feel good. I also had

painted example of my VRR/NH Mile Markers and W, A & R post. Additionally,

as a last-minute decision I brought up some older failed test prints of the

L&NE wooden gondola and HT&W snowplow. In my mind these was a good

collection of my work and by far was the most colorful and whimsical collection

at the show.

The show

was held at a La Quinta Hotel in Springfield, MA just north of the Springfield

Train Station and I booked a night to make sure I didn’t miss anything.

|

| Obligatory Railfan Picture of the Station |

Good

thing I did as Fridays event didn’t end till past 10:30 pm. The hotel’s

convention/ballroom space was located on the top (12th) floor which was a

little weird seeing as most hotels have this on the first floors. From what I

was able to gather there was some sort of round spinning restaurant that once

used this space in the late 1970s but I’m not exactly sure. Regardless the room

was spacious for many models display tables, vender booths raffle tables and

white elephant tables.

|

| Lou's Model OF LIRR No. 400, Once VRR 0800 and now at the CERM. |

|

| HO scale Rail Ferry |

Railroad and modeling clinics were held almost every hour

being held in conference rooms on the 2nd and 11th floor. Again, this was a bit

problematic at times because of only 2 of the 4 elevators working. And

actually, was the cause of me missing a part if not all of talks. The ones I

was able to attend were very informative and inspired me to continue working on

my models. The hotel room itself was also a bit dated but was at least

comfortable and the included breakfast buffet was great. Overall, I’d give the

venue a solid 6.5/10. Not the worst hotel ever but could use some updating and

the entire elevator situation was annoying but manageable. Also seeing as this

is my first event, I really have nothing better or worse to compare to.

|

| Overview of the Room |

|

| Overview of the Room. |

Next

up, another major reason I attended the event and I’m happy to finally be able

to officially announce a major project I have been working on over the last few

months!! During this time, myself and Randy Hammill, have been working together

along with John Green of Bethlehem Car Works to create and produce kits of some

New Haven Deluxe coach, smoker, and Combine cars. These kits, when produced

will be made of resin sides that fit on existing Branchline coach cores. The

side will be cast from 3D printed masters that I have created with help of

Randy’s in-depth research. I am very excited to be apart of this team and use

my skills to help create these products!! The NERPM was our first official

announcement of the project and included 3d printed test prints on display

along with reference photos and drawings. And now since the cat is out of the

bag Randy and I will be making more regular post on our respective blogs about

the progress of these models. The hope

and goal are to have some kits ready for the New Haven Railroad Historical and

Technical Association’s model train show/ reunion later this September. And if

this first batch of cars is successful, we are already looking to continue this

project with additional cars based on some of the NH’s Pullman Parlor cars. Its

all very exciting and I’m so happy to finally be able to share this with you

all. I hope you find this as exciting as we do!!

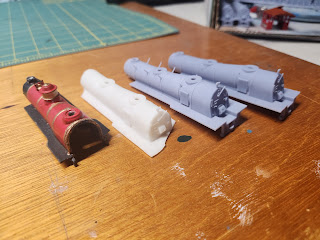

|

| Examples of the Combine and Deluxe Coach Cars |

Finally, I wanted to share with you all the “haul” of items

I picked up at the show. I bought 2 things and the rest I got very lucky with

the two days of Raffles.

|

| The show Haul and example of new Business Cards |

From right to left there is a Bethlehem Car Works NH

Heavyweight Diner Car, Ether the Dreadnought or John Bertram the cars found of

the Yankee Clipper. A Lasor cut Station Kit of Southampton Station, Which I won

Friday night in the Raffle by being the only one to put a ticket in the bag. A

Scale Trains beverage holder, Free. Two packs of Micro Trains N scale US army

Humvees, again won by being the only one to bid on them. A Walther’s Trainline

Eire-Lackawanna SW8 Switcher, which was one of the craziest wins as I only

entered one ticket in and won!!

There

were a few items I missed out on which was slightly disappointing but Ill take

what I got and for only spending $25 on tickets I think I made out fine.

Last but certainly not least, in my opinion, the best items

I got at the show was a HO scale laser cut wooden model of Essex Station!! It

was the first thing I found on the White Elephant tables and held onto it until

it was open for business!! Sadly, I

don’t believe it is a full kit but It’s still a win in my mind as I can use the

parts I do have to as a base to create other replacement parts. And having the

kit in hand is already giving me ideas on building a small diorama of Essex

Station to place 3025 and 0901 in front of.

And that’s about it for my report. Overall, I had a great

time with the show and am looking forward to more in the future. Thank you to

all of the friends that encouraged me to attend the show and for making the

show itself very enjoyable. (Chris, Bill, Randy, Kaylee, Lou just to name a

few) I hope you also enjoyed my recap and are looking forward to the next

adventure here at the workshop. Till then see you real soon.